I designed an RFID labeling machine capable of placing 9X12mm RFID labels onto Keurig Vue cups moving on an open conveyor. System is able to apply at a rate of up to 1000 cups per minute with +/- 3mm placement accuracy. This is a bolt-on design intended to be installed on existing packaging lines with open conveyors carrying cups to a secondary packaging machine. I assembled and installed 8 of these units into production.

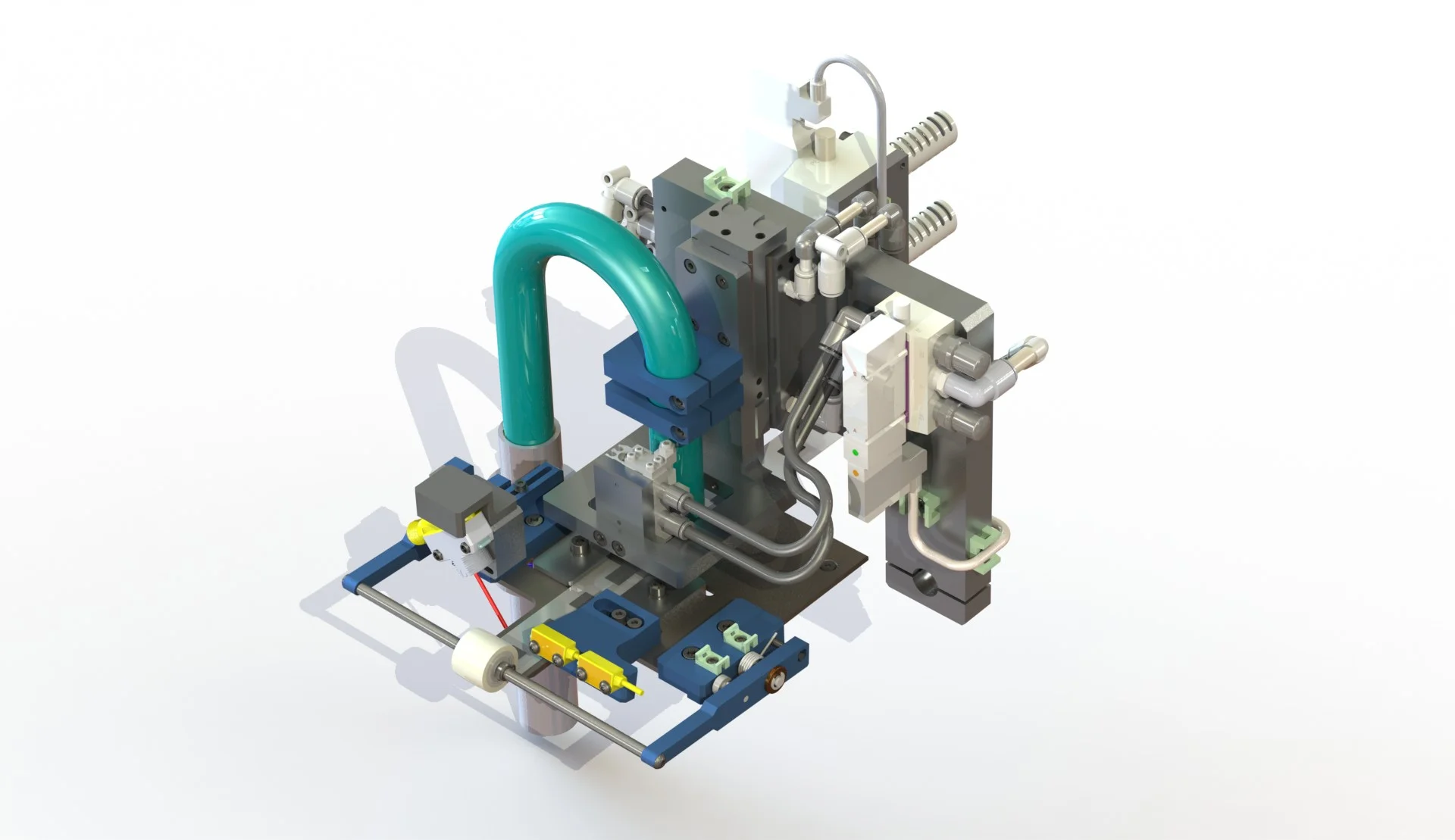

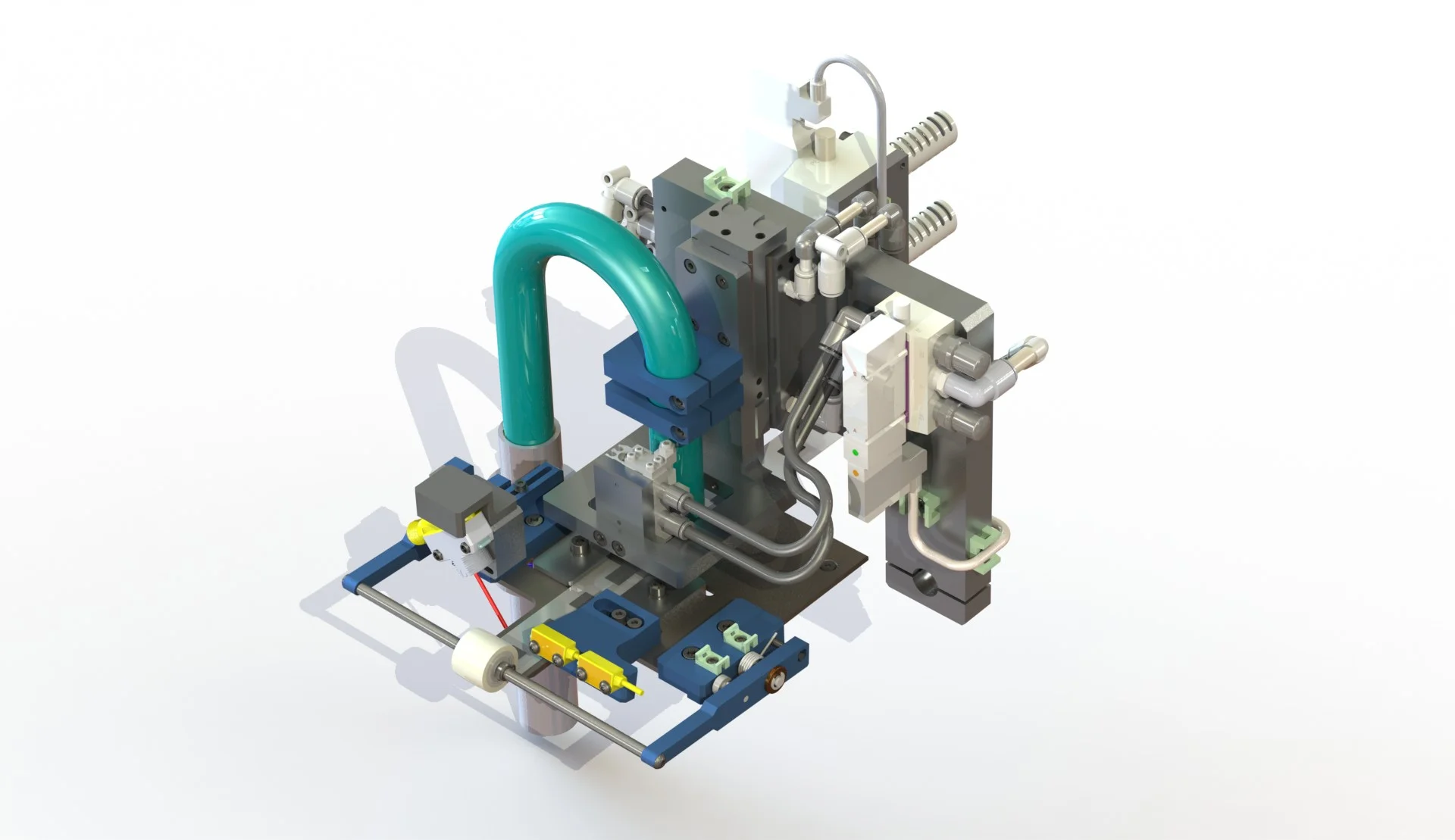

The majority of the design work was focused on the labeling mechanism seen here. Parallel detection sensors make sure that only carriers with cups present trigger a label placement. The labeling mechanism includes a reject system that detects a registration mark printed next to a known bad label. The bad label is registered and once it reaches the reject position, a blade is extended to peel the label during the next web advance. Vacuum is engaged during peel to take away and collect rejected labels. The system is capable of removing 3 labels in a row without missing a good label placement on a cup.

The Carrier is seen here. The belt drive captures the carriers on the open conveyor and applies a fixed speed. I use an encoder on the idler end of the belt drive system to inform my web speed.