Prototyping potential change to an existing consumable to assess feasibility before investing in tool change. Designed in SW, toolpath generated in SW/HSMWorks, machined on Haas, Silicone mold made, polyurethane parts cast for testing.

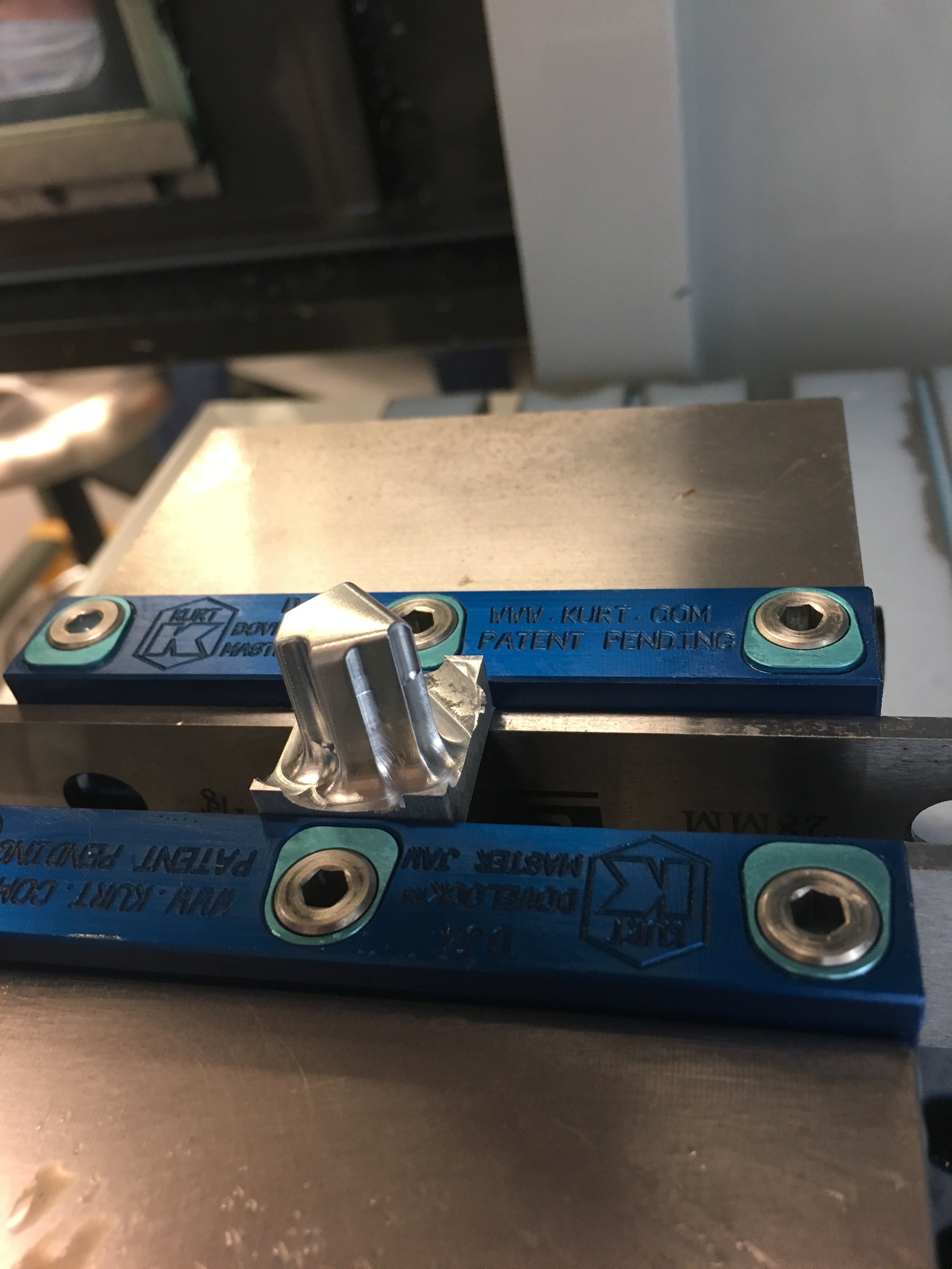

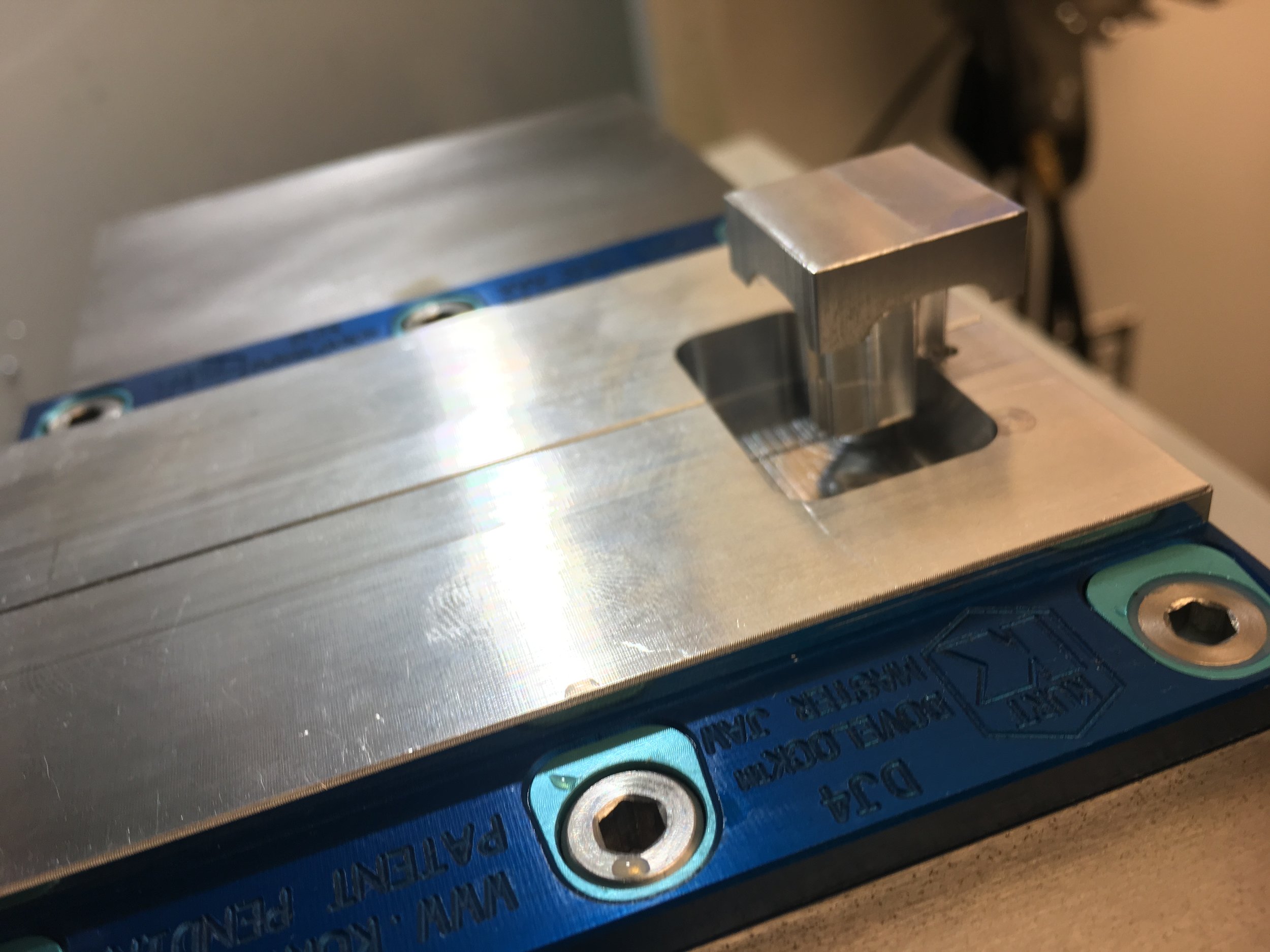

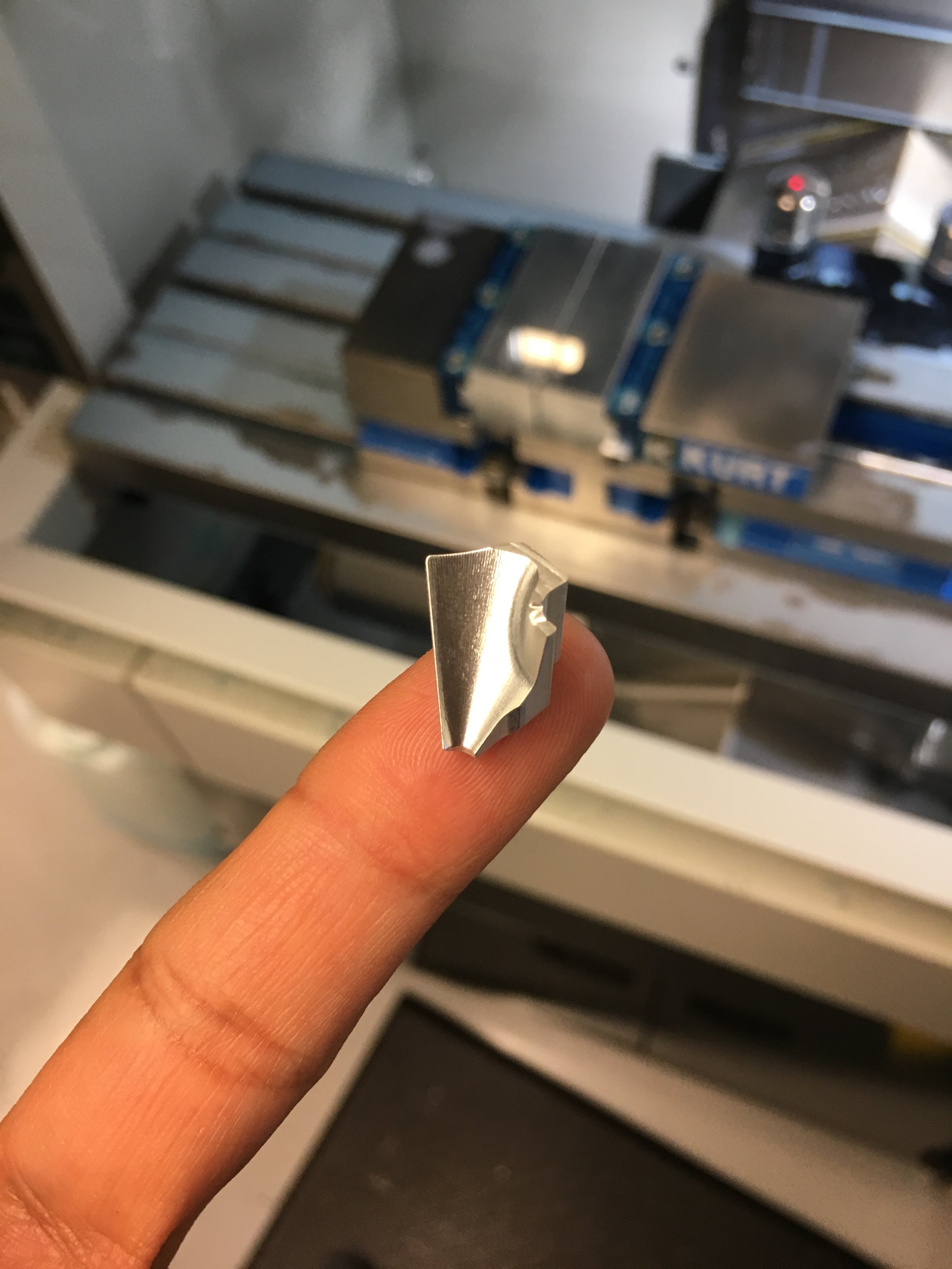

Updated HSM, machined new soft jaw and created new master, shown here with old

Updated HSM, machined new soft jaw and created new master, shown here with old

Early prototype of what will become the probe library production module, shown here.

Machining an optical alignment reticle holder for the dropmaker module clamp. Designed in Solidworks, CAM in HSMWorks, machined on ProtoTrak CNC milling machine.

Finished part shown here after precision reticle was UV epoxy bonded into place. This part is used to perform initial alignment on the dropmaker clamp assembly shown here.

The laser cutter is a very powerful and super quick method for prototyping or creating real parts. Here I used it to make a set of cartridge stands to aid Biologists in their sample preparation process

Here is a functional SLA of a lab consumable that I designed. It consists of reagent wells above and press-fit connections to a microfluidic device below.

Here is a functional SLA of a lab consumable that I designed. It consists of reagent wells above and press-fit connections to a microfluidic device below.

Shown here with PDMS microfluidic device installed.

Shown here with PDMS microfluidic device installed.

This prototype aided in the development of the inverse funnel well plate, shown here. The buoyancy of the emulsion relative to the carrier oil is leveraged in order to simplify the extraction process. This prototype led to the eventual development and design of the emulsification and extraction modules shown here.